Introduction to Contract Price for Construction Projects

Introduction:

Construction projects that involve import and export elements have complex pricing structures due to various factors. The Contract Price, also known as the total cost, is the amount that the contractor charges the owner for completing a construction project. It includes all the expenses associated with the project, including the cost of materials, labor, equipment, and overheads.

The Contract Price for construction projects with import and export elements is influenced by various factors, such as the scope of work, updates in legislation, fluctuations in exchange rates, transportation costs, and customs duties. Changes in any of these factors can have a significant impact on the Contract Price, which makes it crucial to have a thorough understanding of the pricing structure.

This chapter will provide a comprehensive explanation of the factors that influence the Contract Price, including potential changes due to variations in the scope of work, updates in legislation, and other relevant conditions. It will also discuss the import and export elements of the Contract Price and how they impact the pricing structure.

Factors that Influence the Contract Price:

The Contract Price for construction projects with import and export elements is influenced by various factors. Understanding these factors is crucial for both the owner and the contractor to determine the appropriate pricing structure for the project. Some of the significant factors that influence the Contract Price are discussed below:

1. Scope of Work

The scope of work refers to the specific tasks and activities that need to be completed to deliver the project successfully. Changes in the scope of work can have a significant impact on the Contract Price. For instance, if the owner requests additional work that was not included in the original contract, the contractor may need to adjust the Contract Price accordingly.

Explanation: Scope of Work Changes

A construction company in Canada is contracted to build a new office building. The initial Contract Price is CAD 10 million, which includes the cost of materials, labor, equipment, and overheads. However, halfway through the project, the owner requests additional work to be completed, such as adding a rooftop garden. The contractor needs to adjust the Contract Price to CAD 11 million to reflect the additional work requested by the owner.

2. Updates in Legislation

Legislation updates can impact the Contract Price of construction projects, especially those with import and export elements. For example, if there are changes in the customs duties or taxes on imported materials, the contractor may need to adjust the pricing structure to reflect these changes. Additionally, changes in environmental regulations or building codes can also affect the Contract Price.

Explanation: Updates in Legislation

A construction company in the United Kingdom plans to import steel beams from Germany for a construction project. The initial Contract Price is £800,000, which includes the cost of the steel beams, transportation costs, and customs duties. However, two months later, the UK government imposes new customs duties on imported materials from Germany. As a result, the contractor needs to adjust the Contract Price to £900,000 to reflect the increased cost of importing the materials.

3. Fluctuations in Exchange Rates

Fluctuations in exchange rates can have a significant impact on the Contract Price for construction projects with import and export elements. For instance, if the currency of the country where the materials are being imported from strengthens against the local currency, the cost of importing those materials will increase. This, in turn, will lead to an increase in the Contract Price.

Explanation: Fluctuations in Exchange Rates

A construction company in the United States plans to import steel beams from China for a construction project. The initial Contract Price is $1 million, which includes the cost of the steel beams, transportation costs, and customs duties. However, six months later, the exchange rate between the US dollar and the Chinese yuan changes, and the cost of importing the steel beams increases by 10%. As a result, the contractor needs to adjust the Contract Price to $1.1 million to reflect the increased cost of importing the materials.

4. Transportation Costs

Transportation costs are another factor that can influence the Contract Price. The cost of transporting materials, equipment, and labor to the construction site can vary based on the distance, mode of transportation, and the type of materials being transported. Additionally, changes in fuel prices can also impact transportation costs.

5 .Customs Duties

Customs duties are taxes that are imposed on goods when they cross a country’s border. Customs duties can significantly impact the Contract Price for construction projects that involve importing materials from other countries. The contractor may need to pay customs duties on imported materials, which will increase the overall cost of the project.

Construction projects that involve importing and exporting materials have a more complex pricing structure than projects that only use locally sourced materials. Understanding the import and export elements of the Contract Price is crucial to developing an accurate pricing structure for the project.

5.1 Imported Materials

The cost of imported materials is a significant factor in the Contract Price of construction projects with import and export elements. The contractor needs to consider the cost of the materials, transportation costs, and customs duties when developing the pricing structure. The contractor may also need to consider the lead time for importing materials, as delays in the delivery of materials can impact the overall project timeline and budget.

For example, consider a construction project that involves importing steel beams from China. If the exchange rate between the local currency and the Chinese yuan changes, it could significantly impact the cost of importing the steel beams. Additionally, if there are changes in the customs duties or taxes imposed on imported materials, the contractor will need to adjust the Contract Price accordingly.

5.2 Exported Materials

Exported materials are also a significant factor in the Contract Price for construction projects with import and export elements. The contractor may need to export materials, such as steel or concrete, to other countries to complete the project. The cost of exporting materials will depend on various factors, such as the destination country, transportation costs, and customs duties.

For example, consider a construction project that involves exporting concrete to a neighboring country. If the exchange rate between the local currency and the currency of the destination country changes, it could impact the cost of exporting the concrete. Additionally, if there are changes in the customs duties or taxes imposed on exported materials, the contractor will need to adjust the Contract Price accordingly.

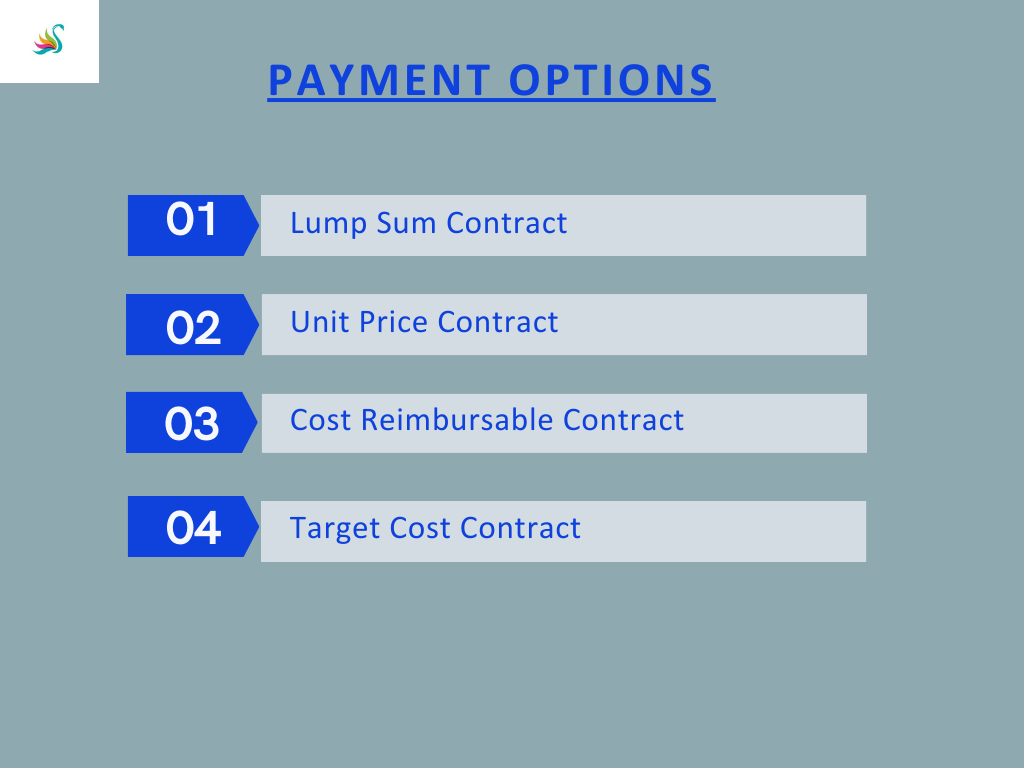

Types of Payment Options within Construction Industry

In power plant construction contracts, there are several common types of payment options that contractors and project owners can consider. These options can have varying benefits and drawbacks, and the selection of a payment option should be based on a careful analysis of specific project circumstances and the goals of the parties involved. Here is a detailed explanation of the most commonly used payment options in power plant construction contracts:

1. Lump Sum Contract:

A lump sum contract involves a fixed total price for the project as a whole. Under this option, the contractor agrees to deliver the completed power plant for a specific price, regardless of the actual costs incurred in construction. This payment option provides certainty in terms of financial commitment, as the project owner knows the exact cost upfront. It also places the burden of any cost overruns on the contractor. However, contractors may include contingencies in the lump sum price to factor in potential risks, which could increase the overall cost for the project owner.

A real-world example of a lump sum contract in power plant construction is the Vogtle Electric Generating Plant in Georgia, USA. The project owner, Georgia Power, contracted Southern Nuclear Operating Company to construct two new nuclear reactors under a lump-sum contract.

2. Unit Price Contract:

In a unit price contract, the project owner pays the contractor based on the quantities of defined items in the power plant, such as equipment, materials, or labor. Prices for each unit are predetermined and agreed upon in advance. This payment option is suitable when the actual quantities of different components of the power plant are uncertain or may change during the construction phase. The project owner can monitor the quantities closely and only pay for what is actually delivered. However, the drawback is that if the actual quantities are significantly higher than estimated, the project owner may face increased costs.

An example of a unit price contract is the construction of wind farms, where the project owner pays the contractor based on the number of wind turbines installed.

3. Cost Reimbursable Contract:

In a cost reimbursable contract, the project owner agrees to reimburse the contractor for the actual costs incurred in construction, including labor, equipment, materials, and overheads. This payment option provides the contractor with maximum flexibility to manage the project and adjust to unforeseen circumstances, as the project owner bears the risk of cost overruns. On the other hand, the project owner has less cost certainty, as the final cost of the project may not be clear until its completion. To mitigate this, cost reimbursable contracts often include a maximum price limit or a guaranteed maximum price.

An example of a cost reimbursable contract in power plant construction is the Hinkley Point C nuclear power station in the UK, where the project owner, EDF Energy, awarded a contract to Bouygues TP-Ledun Construction JV on a cost reimbursable basis.

4. Target Cost Contract:

A target cost contract is a variant of a cost reimbursable contract where the project owner and contractor agree on a target cost for the project. The contractor is then rewarded or penalized based on the difference between the actual costs and the target cost. If the actual costs are below the target cost, the contractor is usually entitled to a share of the savings as an incentive. Conversely, if the actual costs exceed the target cost, the contractor may be required to bear a portion of the excess costs. This payment option allows for shared risk and encourages cost control by the contractor. However, it requires a significant level of collaboration and cooperation between the parties to determine the target cost and the sharing arrangement.

A real-world example of a target cost contract in power plant construction is the Sellafield MOX Plant in the UK, where the project owner, Sellafield Ltd, employed a target cost contract with the Doosan Babcock-Insight JV.

Factors to Consider when Selecting a Payment Option:

When selecting a payment option for a power plant construction project, contractors and project owners should consider several factors including:

Project complexity: The more complex the project, the more flexible the payment option may need to be to account for uncertainties.

Cost and risk allocation: Consideration should be given to the party best suited to manage and bear the risk associated with cost overruns.

Financial capacity and cash flow: Both parties should assess their financial positions and determine if they have the necessary capacity to commit to a particular payment option.

It is essential for contractors and project owners to consult relevant industry standards and best practices when selecting a payment option. These may include guidelines published by professional organizations like the International Federation of Consulting Engineers (FIDIC) or industry-specific standards set by regulatory bodies.

Conclusion:

In conclusion, the Contract Price for construction projects is a complex pricing structure that is influenced by various factors, such as the scope of work, updates in legislation, fluctuations in exchange rates, transportation costs, and customs duties. Changes in any of these factors can have a significant impact on the Contract Price, which makes it crucial to have a thorough understanding of the pricing structure. The import and export elements of the Contract Price are also important factors that need to be considered when developing an accurate pricing structure for the project. By understanding the various factors that influence the Contract Price, contractors and owners can develop an appropriate pricing structure that accurately reflects the costs associated with the project.